Safety Eligibility Letter CC-115F

1200 New Jersey Ave. S.E.

Washington, D.C. 20590

May 1, 2013

In Reply Refer To: HSST/CC-115F

Mr. Brian Smith

Trinity Highway Products, LLC

2525 North Stemmons Freeway

Dallas, Texas 75207

Dear Mr. Smith:

This correspondence supersedes existing eligibility letter HSST/CC-115C dated December 21, 2012 and is in response to your request for additional system details for furthered consideration for Federal Highway Administration (FHWA) review of the as-described roadside safety system for eligibility for reimbursement under the Federal-aid highway program.

| Name of system: | Trinity TL1 SOFT-STOP Terminal |

|---|---|

| Type of system: | W-Beam Guardrail Terminal |

| Test Level: | MASH Test Level 1 (TL1) |

| Testing conducted by: | Original testing by Texas Transportation Institute |

| Task Force 13 Designator: | SEW22C |

| Date of request: | January 23, 2013 |

| Date to final package | April 12, 2013 |

Decision:

The following device is eligible, with details provided in the form which is attached as an integral part of this letter.

- Trinity TL1 SOFT-STOP Terminal

Based on a review of previous crash tests submitted by the manufacturer certifying the device described herein meets the crash test and evaluation criteria of the American Association of State Highway and Transportation Officials' Manual for Assessing Safety Hardware (MASH), the device is eligible for reimbursement under the Federal-aid highway program. Eligibility for reimbursement under the Federal-aid highway program does not establish approval or endorsement by the FHWA for any particular purpose or use.

The FHWA, the Department of Transportation, and the United States Government do not endorse products or services and the issuance of a reimbursement eligibility letter is not an endorsement of any product or service.

Requirements

To be found eligible for Federal-aid funding, roadside safety devices should meet the crash test and evaluation criteria contained in the American Association of State Highway and Transportation Officials’ Manual for Assessing Safety Hardware (MASH).

Description

The device and supporting documentation are described in the attached form.

Summary and Standard Provisions

Therefore, the system described and detailed in the attached form is eligible for reimbursement and may be installed under the range of conditions tested.

Please note the following standard provisions that apply to FHWA eligibility letters:

- This letter provides a AASHTO/ARTBA/AGC Task Force 13 designator that should be used for the purpose of the creation of a new and/or the update of existing Task Force 13 drawing for posting on the on-line ‘Guide to Standardized Highway Barrier Hardware’ currently referenced in AASHTO Roadside Design Guide.

- This finding of eligibility does not cover other structural features of the systems, nor conformity with the Manual on Uniform Traffic Control Devices.

- Any changes that may influence system conformance with MASH will require a new reimbursement eligibility letter.

- Should the FHWA discover that the qualification testing was flawed, that in-service performance reveals safety problems, or that the system is significantly different from the version that was crash tested, we reserve the right to modify or revoke this letter.

- ou are expected to supply potential users with sufficient information on design and installation requirements to ensure proper performance.

- You are expected to certify to potential users that the hardware furnished has the same chemistry, mechanical properties, and geometry as that submitted for review, and that it will meet the test and evaluation criteria of the MASH.

- To prevent misunderstanding by others, this letter of eligibility is designated as number CC-115F and shall not be reproduced except in full. This letter and the test documentation upon which it is based are public information. All such letters and documentation may be reviewed at our office upon request.

- This letter shall not be construed as authorization or consent by the FHWA to use, manufacture, or sell any patented system for which the applicant is not the patent holder. The FHWA does not become involved in issues concerning patent law. Patent issues, if any, are to be resolved by the applicant.

- The Trinity SOFT-STOP Terminal is a patented product and considered proprietary. If proprietary systems are specified by a highway agency for use on Federal-aid projects: (a) they must be supplied through competitive bidding with equally suitable unpatented items; (b) the highway agency must certify that they are essential for synchronization with the existing highway facilities or that no equally

suitable alternative exists; or (c) they must be used for research or for a distinctive type of construction on relatively short sections of road for experimental purposes. Our regulations concerning proprietary products are contained in Title 23, Code of

Federal Regulations, Section 635.411.

|

Sincerely yours, /* Signature of Michael S. Griffith */

|

|||

Enclosures

Request for Federal Aid Reimbursement Eligibility

Of Highway Safety Hardware

| Submitter | Date of Request: | April 12, 2013 |

| Name: | Don Gripne | |

| Company: | TRINITY HIGHWAY PRODUCTS, LLC | |

| Address: | 2525 STEMMONS FREEWAY, DALLAS, TX 75207 | |

| To: | Michael S. Griffith, Director FHWA, Office of Safety Technologies |

I request the following devices be considered eligible for reimbursement under the Federal-aid highway program.

| System Type | Device Name/Variant | Testing Criterion | Test Level |

|---|---|---|---|

| 'CC': Crash Cushions, Attenuators, & | Trinity TL-2 SOFTSTOP Terminal | AASHTOMASH | TL1 |

By submitting this request for review and evaluation by the Federal Highway Administration, I certify that the product(s) was (were) tested in conformity with the AASHTO Manual for Assessing Safety Hardware and that the test of evaluation results meet the appropriate evaluation criteria in the MASH.

Identification of the individual or organization responsible for the product: /s/ Don Jay Gripne

| Contact Name: | BRIAN SMITH |

| Company Name: | TRINITY HIGHWAY PRODUCTS, LLC |

| Address 1: | 2525 STEMMONS FREEWAY |

| Address 2: | |

| City/State/Zip | DALLAS, TX 75207 |

| Country: | USA |

Request for Federal Aid Reimbursement Eligibility

Of Highway Safety Hardware

| Submitter | Date of Request: | April 12, 2013 |

| Name: | Don Gripne | |

| Company: | TRINITY HIGHWAY PRODUCTS, LLC | |

| Address: | 2525 STEMMONS FREEWAY, DALLAS, TX 75207 | |

| To: | Michael S. Griffith, Director FHWA, Office of Safety Technologies |

I request the following devices be considered eligible for reimbursement under the Federal-aid highway program.

| System Type | Device Name/Variant | Testing Criterion | Test Level |

|---|---|---|---|

| 'CC': Crash Cushions, Attenuators, & | Trinity TL-1 SOFTSTOP Terminal | AASHTO MASH | TL1 |

By submitting this request for review and evaluation by the Federal Highway Administration, I certify that the product(s) was (were) tested in conformity with the AASHTO Manual for Assessing Safety Hardware and that the test I evaluation results meet the appropriate evaluation criteria in the MASH.

Identification of the individual or organization responsible for the product:

| Contact Name: | BRIAN SMITH |

| Company Name: | TRINITY HIGHWAY PRODUCTS, LLC |

| Address 1: | 2525 STEMMONS FREEWAY |

| Address 2: | |

| City/State/Zip | DALLAS, TX 75207 |

| Country: | USA |

PRODUCT DESCRIPTION

Modification to Existing Hardware Non-Significant – Effect is positive or Inconsequential

The original crash test of the Trinity Soft Stop (TTI Crash Report 2009) as per Eligibility Letter CC-115 dated December 19, 2011 specified steel post and w-beam guardran using 12-inch wood block out. The crash test was conducted by Texas Transportation Institute (TTI) entitled NCHRP 350 Crash Testing and Evaluation of the Vertical Squlsher' dated February 2009 (TTI Crash Report 2009). Eligibility Letter CC-115A dated September 7, 2012 was issued to include B-lnch wood block out for both line posts and post no 2 within the Trinity Soft Stop Terminal system. This modification also Includes an offset 2·foot from tangent of the 12-inch and 8-inch Trinity Soft Stop Terminal system using a flare rate of 25:1.

!The length required to dissipate the energy of the 2270P test vehicle Is calculated to be 11.0 feet (3.3 m) for MASH TL-1. The calculated test results is on file with this request. The effective length of the requested TL-1 Soft Stop Terminal is 13'-3 1/2".

This request Is to acceptthe as-tested article as per CC·11S and CC·11 SA for the following:

- A MASH TL·1 Soft Stop Terminal with a length of 13'·31/2".

- 12 inch or 8 inch wood/composite block outs.

- An offset 1/2-foot from tangent. flare rate of 25:1.

- For attachment to 8-lnch/12-inch block out systems or no blackout W·beam guardrail systems.

This modification is considered Non-significant, Effect is Positive or inconsequential.

CRASH TESTING

A brief description of each crash test and its result:

| Required Test Number | Narrative Description | Evaluation Results |

|---|---|---|

| 1-30 (1100C) | As per TTI Crash Report 2009, an 1100C (2425 lb) passenger car impacting the terminal end-on at a nominal impact speed and angle of 62 mi/h and 0 degree, respectively, with the quarter point of the vehicle aligned with the center line of the nose of the terminal. This test is primarily intended to evaluate occupant risk and vehicle trajectory criteria. The SOFT-STOP slowed and redirected the 1100C vehicle. No occupant compartment deformation occurred. The 1100C vehicle remained upright during and after the collision event. Maximum roll was 25 degrees, and maximum pitch was 7 degrees. Occupant risk factors were within the limits specified for MASH test 3-30. The vehicle subsequently came to rest 27 feet downstream of impact and 34 feet toward traffic lanes. The SOFT-STOP performed acceptably according to the evaluation criteria of MASH test 3-30. | WAIVER REQUES |

| 1-31 (2270P) | As per TTI Crash Report 2009, A 2270P (5000 lb) pickup truck impacting the terminal end-on at a nominal impact speed and angle of 62 mi/h and 0 degree, respectively, with the center line of the vehicle aligned with the center line of the nose of the terminal. This test is primarily intended to evaluate occupant risk and vehicle trajectory criteria. The SOFT-STOP brought the 2270P vehicle to a controlled stop. No occupant compartment deformation occurred. The 2270P vehicle remained upright during and after the collision event. Maximum roll was 4 degrees, and maximum pitch was -3 degrees. Occupant risk factors were within the limits specified for MASH test 3-31. The 2270P vehicle came to rest within the installation. The SOFT-STOP performed acceptably according to the evaluation criteria of MASH test 3-31. | WAIVER REQUES |

| 1-32 (1100C) | As per TTI Crash Report 2009, an 1100C (2425 lb) passenger car impacting the terminal end-on at a nominal impact speed and angle of 62 mph and 5/15 degrees, respectively, with the center line of the vehicle aligned with the center line of the nose of the terminal. This test is primarily intended to evaluate occupant risk and vehicle trajectory criteria. The SOFT -STOP slowed and stopped the 1100C vehicle. No occupant compartment deformation occurred. The 1100CC vehicle remained upright during and WAIVER REQUES after the collision event. Maximum roll was 28 degrees, and maximum pitch was -26 degrees. Occupant risk factors were within the limits specified for MASH test 3-32. The vehicle subsequently came to rest with the front of the vehicle adjacent to post 4 of the terminal, with most of the vehicle toward the field side. The SOFT-STOP performed acceptably according to the evaluation criteria of MASH test 3-32. | WAIVER REQUES |

| 1-33 (2270P) | As per TTI Crash Report 2009, the 2000P vehicle, traveling at an impact speed of 62.7 mi/h, impacted the nose of the Vertical Squisher end-on at an impact angle of 16.3 degrees. At 0.044 s after impact, the head of the terminal began to move along the rail, and at 0.093 s, the 2000P vehicle began to redirect toward the field side. The front right tire contacted the terminal at 0.207 s. The vehicle began to travel parallel with the guardrail at 0.285 s, at a speed of 48.2 mi/h (77.6 km/h). At 0.372 s, the 2000P vehicle overrode the terminal and lost contact with the guardrail and was traveling at an exit speed and angle of 51.7 mi/h (83.2 km/h) and 1.8 degrees, respectively. After completely exiting the installation, the 2000P vehicle partially traversed a steep mound of soil and came to rest on its right side 242 ft downstream and 30 ft toward the field side. | WAIVER REQUES |

| 1-34 (1100C) | As per TTI Crash Report 2009, an 1100C (2425 lb) passenger car impacting the terminal at a nominal impact speed and angle of 62 mi/h and 15 degrees, respectively, with the comer of the vehicle bumper aligned with the critical impact point (CIP) of the length of need (LON) of the terminal. This test is primarily intended to evaluate occupant risk and vehicle trajectory criteria. The SOFT-STOP contained and redirected the 1100C vehicle. The vehicle did not penetrate or override the installation. Maximum dynamic deflection was 1.96 feet and the head fed through 6.2 feet of w-beam rail element. Maximum occupant compartment deformation was 1.0 inch inward in the area of the instrument panel on the left side. The 1100C vehicle remained upright during and after the collision event. Maximum roll was 10 degrees, and maximum pitch was -4 degrees. Occupant risk factors were within the limits specified for MASH test 3-34. The vehicle subsequently came to rest 15 feet toward traffic lanes in front of post 8. The SOFT-STOP performed acceptably according to the evaluation criteria of MASH test 3-34. | WAIVER REQUES |

| 1-35 (2270P) | As per TTI Crash Report 2009, a 2270P (5000 lb) pickup truck impacting the terminal at a nominal impact speed and angle of 62 mi/h and 25 degrees, respectively, with the comer of the vehicle bumper aligned with the beginning of the LON of the terminal. This test is primarily intended to evaluate structural adequacy and vehicle trajectory criteria. The SOFTSTOP contained and redirected the 2270P. The vehicle did not under ride or override the installation. Although the w-beam rail anchorage released late in the impact event, the vehicle did not penetrate the installation. While the vehicle was in contact with the w-beam, the maximum dynamic deflection was 10.4 feet However, the upstream anchor released and as the vehicle lost contact with the w-beam, the w-beam continued to deflect, reaching a maximum displacement of 11.6 feet. The kickpanel of the left side was deformed inward 0.4 inch. The 2270P vehicle remained upright during and after the collision event. Maximum roll was -30 degrees, and maximum pitch was -12 degrees. Occupant risk factors were within the preferred limits specified for MASH test 3-31. The 2270P vehicle exited within the exit box. The SOFT-STOP performed acceptably according to the evaluation criteria of MASH test 3-35. | |

| 1-36 (2270P) |

As per TTI Crash Report 2009, a 2270P (5000 lb) pickup truck impacting the terminal at a nominal impact speed and angle of 62 mi/h and 25 degrees, respectively, with the comer of the vehicle bumper aligned with the CIP with respect to the transition to the stiff barrier or backup structure. As a w-beam guardrail terminal, the SOFT-STOP will never be attached directly to a backup structure, and the transition to a stiff barrier is basically at Post 3. Therefore, Trinity feels that Test 3-36 is irrelevant and was therefore not conducted. |

WAIVER REQUES |

| 1-37 (2270P) | As per TTI Crash Report 2009, a 2270P (5000 1b) pickup truck impacting the terminal at a nominal impact speed and angle of 62 mi/h and 25 degrees, respectively, mid-point between the nose and the end of the terminal in the reverse direction. This test is intended to evaluate the performance of a terminal for a "reverse" hit. However, researchers at TTI believe that the reverse direction impact would be more critical for the 1100C (2425 lb) passenger car than for the 2270P pickup. Therefore, an 1100C (2425 lb) passenger car was used in Test 3-37. Eligibility Letter CC-115 indicated that the substitution of the 1100C vehicle to evaluate the reverse direction impact was appropriate. |

WAIVER REQUES |

| 1-38 (1500A) | As perm Crash Report 2009, a 1500A (3307 lb) passenger car impacting the terminal end-on at a nominal impact speed and angle of 62 mi/h and 0 degree, respectively, with the center line of the vehicle aligned with the center line of the nose of the terminal. This test is primarily intended to evaluate the performance of the staged attenuator/terminal when impacted by a mid-size vehicle. The SOFT-STOP is not a staged device. Therefore Test 3-38 was not conducted. However, as per Appendix G of MASH, calculations based on Test 3-31 have been performed to predict the occupant risk values for the 1500A (3307lb) vehicle. The results of these calculations (shown on the enclosed document) predict that in crash testing with the 1500A (3307lb) vehicle, the SOFT-STOP Terminal, would perform acceptably according to the Test Level3 (TL-3) evaluation criteria set out in the MASH guidelines for terminals. Eligibility Letter CC-115 indicates that test 3-38 is not necessary because the SOFT-STOP is not a staged device and that manufacturers calculations predict crash worthy performance with the 1500A vehicle. |

|

| 1-40 (1100C) | Does not apply to non-gating/energy absorbing devices. | |

| 1-41 (2270P) | Does not apply to non-gating/energy absorbing devices. | |

| 1-42 (1100C) | Does not apply to non-gating/energy absorbing devices. | |

| 1-43 (2270P) | Does not apply to non-gating/energy absorbing devices. | |

| 1-44 (2270P) | Does not apply to non-gating/energy absorbing devices. | |

| 1-45 (2270P) | Does not apply to non-gating/energy absorbing devices. |

Full Scale Crash Testing was done in compliance with MASH by the following accredited crash test laboratory (cite the laboratory's accreditation status as noted in the crash test reports.):

| Laboratory Name: | Texas Transportation Institute |

| Laboratory Contact: | Dean Alberson |

| Address: | 3135 TAMU, College Station, TX. 77843-3135 |

| Country: | USA |

| Accreditation Certificate Number and Date: |

Mechanical 2821.01, Current date April 30, 2013 |

ATTACHMENTS

Attach to this form:

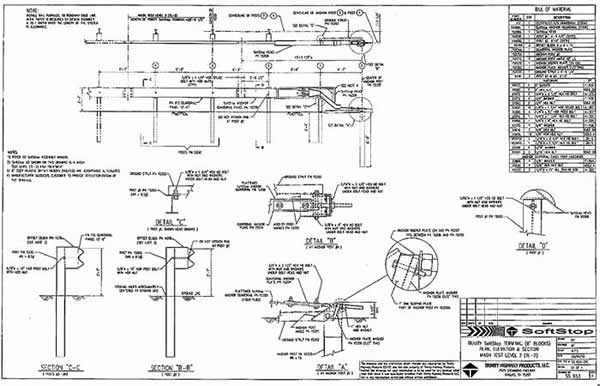

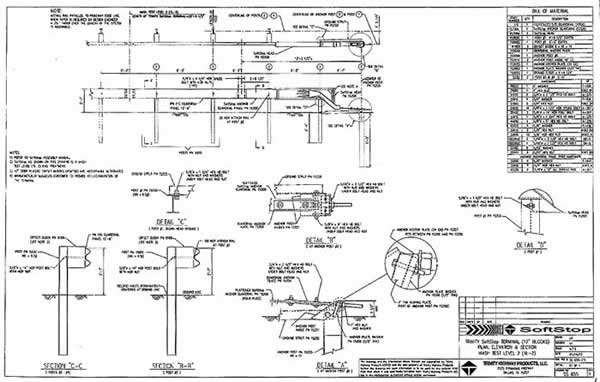

- 1) A copy of the Test Data Summary Sheet for each test conducted in support of this request.

- 2) A drawing or drawings of the device(s) that conform to the Task Force-13 Drawing Specifications [Hardware Guide Drawing Standards]. For proprietary products, a single isometric line drawing is usually acceptable to illustrate the product, with detailed specifications, intended use, and contact information provided on the reverse. Additional drawings (not in TF-13 format) showing details that are key to understanding the performance of the device should also be submitted to facilitate our review.

FHWA Official Business Only:

| Eligibility Letter | AASHTO TF13 | Key Words | |

|---|---|---|---|

| Number | Date | Designator | |

| CC-115C | April 22,2013 | SEW22B | TL1, non-gating/energy absorbing terminal tensioned w-beam guardrail terminal, steel yielding terminal posts, deflector terminal head |

| Inputs and Initial Condition | Value | Units | Description | Outputs | ||

|---|---|---|---|---|---|---|

| M2306.06 | 2306.06 | kg6 | Test vehicle mass | Time@ Max Ridedown Acceleration | 0.1462 | s |

| Vo2306.06 | 98.3309 | km/hr | Test impact velocity | Ridedown Acceleration | -14.8 | g |

| 27.31 | m/s | Time of Occupant Impact | 0.1408 | s | ||

| T2270p | 2 | s | Time for acceleration data acquisition | Occupant Impact Velocity | 7.2 | m/s |

| Msedan | 1100 | kg | Mass of Sedan | |||

| Vosedan | 50 | km/hr | Initial Velocity of Sedan | Max Deflection | 1.6 | m |

| 13.9 | m/s | 5.1 | ft | |||

| Time Step 2306.06 | 0.0001 | s | ||||

| G | 9.81 | m/s^2 | Gravational Constant | |||

| -KEo2306.06 | -860,232 | J | Initial Kinetic Energy 2306.06 | |||

| -KEo2270 | -106.096 | J | Initial Kinetic Energy 2270 | |||

| OIV Travel Distance | 0.60 | m | ||||

| Data Pile Location | T:\20 12-20 13\5I0602\TSQ\Trinity_ Soft_ Stop_ Analysis_ TL2\Data\ASCII\400001ptsq7b001.FIL | |||||

| Inputs and Initial Condition | Value | Units | Description | Outputs | ||

|---|---|---|---|---|---|---|

| M2306.06 | 2306.06 | kg6 | Test vehicle mass | Time@ Max Ridedown Acceleration | 0.3115 | s |

| Vo2306.06 | 98.3309 | km/hr | Test impact velocity | Ridedown Acceleration | -5.8 | g |

| 27.31 | m/s | Time of Occupant Impact | 0.2023 | s | ||

| T2270p | 2 | s | Time for acceleration data acquisition | Occupant Impact Velocity | 5.9 | m/s |

| Msedan | 2270 | kg | Mass of Sedan | |||

| Vosedan | 50 | km/hr | Initial Velocity of Sedan | Max Deflection | 3.3 | m |

| 13.9 | m/s | 11.0 | ft | |||

| Time Step 2306.06 | 0.0001 | s | ||||

| G | 9.81 | m/s^2 | Gravational Constant | |||

| -KEo2306.06 | -860,232 | J | Initial Kinetic Energy 2306.06 | |||

| -KEo1100 | -218,943 | J | Initial Kinetic Energy 2270 | |||

| OIV Travel Distance | 0.60 | m | ||||

| Data Pile Location | T:\20-12-20 13\Trinity_Soft_Stop_Analysis_ TL2\Data\ASCII\400001 ptsq7b001.FIL | |||||