Safety Eligibility Letter B-183

Safety Eligibility Letter B-183

PDF [278 KB]

U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Ave. S.E.

Washington, D.C. 20590

November 26, 2008

In Reply Refer To: HSSD/B-183

Mr. Rick Mauer

Outside National Sales Representative

Nucor Steel Marion Inc.

P.O. Box 837

Greenland, NH 03840

Dear Mr. Mauer:

This letter is in response to your request for Federal Highway Administration (FHWA) acceptance of a modification to Nucor Steel Marion roadside safety systems for use on the National Highway System (NHS).

| Name of system: | Nu-Cable Systems – Use of Plastic or Steel Sockets |

|---|---|

| Use of driven steel sockets | |

| Type of system: | Cable Barrier |

| Test Level: | NCHRP Report 350 TL-3 and TL-4 |

| Testing conducted by: | Holmes Solutions of New Zealand and Texas Transportation Institute |

| Date of request: | July 25, 2006 |

You requested that we find these modified systems acceptable for use on the NHS under the provisions of National Cooperative Highway Research Program (NCHRP) Report 350 “Recommended Procedures for the Safety Performance Evaluation of Highway Features.”

Requirements

Roadside safety systems should meet the guidelines contained in the NCHRP Report 350. The FHWA Memorandum “Action: Identifying Acceptable Highway Safety Features” of July 25, 1997, provides further guidance on crash testing requirements of longitudinal barriers.

Description

The Nu-Cable barrier systems consist of three or four steel cables mounted on 4 lb/ft Nucor Steel Marion Rib-Bak u-channel posts. These systems were found acceptable in the following FHWA acceptance letters:

B-96 August 30, 2002 3-strand roadside or median barrier

B-96A October 12, 2005 Alternative post and foundation designs

B-167 February 24, 2008 4-strand Nucor Wire Rope Barrier System TL-4

Crash Testing

All test level 3 (TL-3) and TL-4 barriers were tested in either plastic socket sleeves (New Zealand tests) or steel socket sleeves (Texas tests) encased in a rebar fortified concrete foundation. No difference in performance was noted between the two types of sleeves. Your request is to allow the interchangeability of the two foundation systems on your Nu-Cable systems. We concur in this request for new installations. When barrier installations are damaged to the degree that the post foundations are affected, repairs should be made using the same foundation systems they were tested with to the extent practicable.

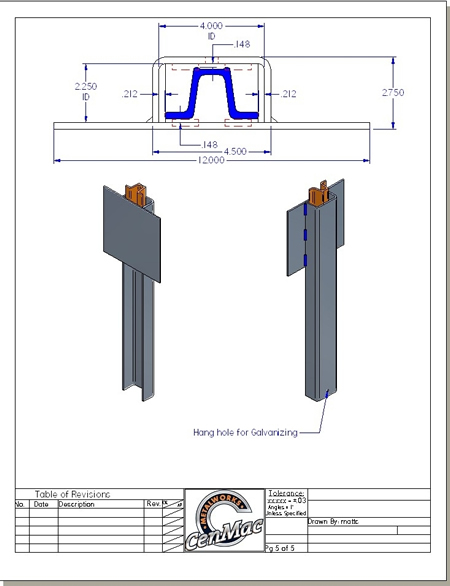

You also requested the use of driven steel socket sleeves for 4-pound-per-foot u-channel posts, as shown in the enclosed drawing. Informal vehicle testing in standard soil showed no perceptible movement of the socket.

Findings

The following Nu-Cable System modifications acceptable for use on the NHS under the range of conditions tested, when such use is acceptable to a highway agency:

1) Posts mounted in plastic socket sleeves encased in a rebar fortified concrete foundation,

2) Posts mounted in steel socket sleeves encased in a rebar fortified concrete foundation,

3) Posts mounted in driven socket sleeves with soil plates.

Please note the following standard provisions that apply to the FHWA letters of acceptance:

- This acceptance is limited to the crashworthiness characteristics of the systems and does not cover their structural features, nor conformity with the Manual on Uniform Traffic Control Devices.

- Any changes that may adversely influence the crashworthiness of the system will require a new acceptance letter.

- Should the FHWA discover that the qualification testing was flawed, that in-service performance reveals unacceptable safety problems, or that the system being marketed is significantly different from the version that was crash tested, we reserve the right to modify or revoke our acceptance.

- You will be expected to supply potential users with sufficient information on design and installation requirements to ensure proper performance.

- You will be expected to certify to potential users that the hardware furnished has essentially the same chemistry, mechanical properties, and geometry as that submitted for acceptance, and that it will meet the crashworthiness requirements of the FHWA and the NCHRP Report 350.

- To prevent misunderstanding by others, this letter of acceptance is designated as number B-183 and shall not be reproduced except in full. This letter and the test documentation upon which it is based are public information. All such letters and documentation may be reviewed at our office upon request.

- The Nu-Cable barrier systems are patented products and considered proprietary. If proprietary systems are specified by a highway agency for use on Federal-aid projects, except exempt, non-NHS projects, (a) they must be supplied through competitive bidding with equally suitable unpatented items; (b) the highway agency must certify that they are essential for synchronization with the existing highway facilities or that no equally suitable alternative exists; or (c) they must be used for research or for a distinctive type of construction on relatively short sections of road for experimental purposes. Our regulations concerning proprietary products are contained in Title 23, Code of Federal Regulations, Section 635.411.

- This acceptance letter shall not be construed as authorization or consent by the FHWA to use, manufacture, or sell any patented system for which the applicant is not the patent holder. The acceptance letter is limited to the crashworthiness characteristics of the candidate system, and the FHWA is neither prepared nor required to become involved in issues concerning patent law. Patent issues, if any, are to be resolved by the applicant.

Sincerely yours,

|