Safety Eligibility Letter B-150B

Safety Eligibility Letter B-150B

PDF [193 KB]

U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Ave. S.E.

Washington, D.C. 20590

July 16, 2008

In Reply Refer To: HSSD/B-150B

Mr. Andrew Artar

Vice President Sales and Marketing

Gregory Highway Products

4100 13th Street, SW

Canton, OH 44710

Dear Mr. Artar:

This letter is in response to your request for Federal Highway Administration (FHWA) acceptance of a roadside safety system for use on the National Highway System (NHS).

| Name of systems: | Gregory Mini Spacer (GMS) Guardrail with 12’6” Post Spacing GMS Median Barrier with 12’6” Post Spacing |

|---|---|

| Type of systems: | Steel W-Beam Barriers |

| Test Level: | The National Cooperation Highway Research Program (NCHRP) Report 350 Test Level 3 (TL-3) |

| Testing conducted by: | Southwest Research Institute |

| Date of request: | March 22, 2008 |

| Date of follow up: | April 28, 2008 |

You requested that we find these systems acceptable for use on the NHS under the provisions of the proposed American Association of State Highway and Transportation Officials’ Manual for Assessing Safety Hardware-2008 (MASH-08).

Requirements

Roadside safety systems should meet the guidelines contained in the NCHRP Report 350, "Recommended Procedures for the Safety Performance Evaluation of Highway Features". The FHWA Memorandum “ACTION: Identifying Acceptable Highway Safety Features” of July 25, 1997, provides further guidance on crash testing requirements of longitudinal barriers. However, in this case you have chosen to anticipate the adoption of MASH-08, an option that the FHWA has offered with the understanding that additional testing may need to be done if changes to the test criteria are made before MASH-08 is formally adopted.

Description

The test article was a Modified G4(1S) longitudinal barrier. The length-of-need section consisted of standard unmodified 12-ga W-beam mounted directly to standard unmodified 6 foot long W6 x 8.5 steel posts using the proprietary GMS releasable fasteners. There were no blockouts or backup plates at any of the posts. All guardrail splices were located at the posts.

The posts were embedded to a depth of 44 inches and spaced at 12.5 feet. The Guardrail panels were each 12.5 feet long and mounted such that the top-of-rail height was 27-5/8 inches. The 187-foot long test section was adequately anchored at both ends.

Crash Testing

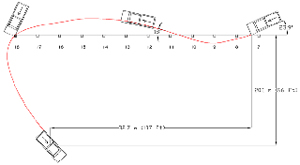

The Gregory Mini Spacer W-Beam Barrier (GMS-WB) was subjected to MASH-08 Test 3-11 using the 5000-pound quad-cab pickup truck. The test data summary sheet is enclosed for reference. Upon impact the barrier deflected 5.0 feet and the vehicle remained upright and in contact with the barrier a total of 46.8 feet. All occupant risk values were within acceptable limits.

Test 3-10 using the 1100C vehicle was waived because the small passenger car has been shown to have insufficient energy to cause significant horizontal deflection or vertical movement in the rail, and that there is little likelihood that it could under-ride the barrier.

Findings

You also requested the following variations to be accepted under MASH-08:

- 1) Single face and double face W-beam versions (Roadside version as crash tested, and median barrier version with W-beam on both sides, both using the GMS.)

- a) The double-face GMS-WB has been previously tested and found acceptable with 6 foot, 3 inch post spacing, meeting both the strength (penetration) and severity (occupant risk) criteria. When extrapolating to the 12 foot, 6 inch post spacing the test with a single rail of W-Beam is the “worst case” condition for both test conditions: for the strength test it is more likely that the vehicle would penetrate the single rail barrier while for the severity test the single rail system is more forgiving.

- 2) GMS-WB for new installations, retrofits, or repairs of 10 gage or 12 gage W-Beam Systems.

- a) Ten gage W-beam is an acceptable alternative for standard 12 gage rail and will be acceptable.

- 3) GMS-WB at top rail heights between 27 inches and 32 inches.

- a) As the lower height rail was tested with the truck having a greater tendency to override the barrier, and the higher rail was previously tested at the 6-foot 3-inch post spacing with the small car having a tendency to go under the rail, the range you requested is acceptable.

- 4) GMS-WB using W6 x 8.5 steel posts or G4(2W) or G4(RW) timber posts.

- a) The performance of these guardrail posts has been demonstrated with crash testing of various barriers and either will be acceptable.

- 5) Splices allowed at or between posts.

- a) As testing was conducted under worst case conditions with splices at posts, splice location will be acceptable at a post or a gap.

- 6) With or without backup plates.

- a) As the rail releases from the post before the edge of the post can tear the rail, backup plates are optional.

- 7) Use of the Gregory Mini-Spacer on any non-proprietary strong or weak post W-beam with or without blockout.

- a) The releasable fastener does not degrade performance of W-beam systems.

- 8) GMS-WB with post spacings of 12 feet 6 inches, 6 feet 3 inches, or 3 feet 1.5 inches.

- a) Testing has verified standard and double spacing. Halved spacing can be expected to reduce deflection as noted:

| 2000P | 2270P | |

|---|---|---|

| Post Spacing | Dynamic Deflection* | Dynamic Deflection** |

| 12 ft 6 in | 5 ft 6 in | 5 ft 10 in |

| 6 ft 3 in | 4 ft 1 in | 4 ft 6 in |

| 3 ft 1.5 in | 3 ft 8 in | 3 ft 11 in |

*Maximum dynamic deflection. The NCHRP Report 350 criteria sets the “design deflection distance” at the maximum dynamic deflection recorded in Report 350 test 3-11. From the crash testing that you performed and your analysis (a method that agrees with a tuned Barrier VII analysis), you came up with recommended Report 350 test 3-11 (2000P) deflection criteria. You recommend that the minimum distances at which the face of a GMS installation be placed from the face of a rigid obstacle (e.g. bridge pier or overhead sign support) be 1.68m (5 ft 6 in), 1.25m (4 ft 1 in), and 1.12m (3 ft 8 in) for 12’6” (2x), standard 6’3” (1x), 3’ 1-1/2” (1/2 x) post spacing, respectively.

**Maximum dynamic deflection. Similarly, for test 3-11 (2270P) as the deflection criteria you recommend that the minimum distances at which the face of a GMS installation be placed from the face of a rigid obstacle (e.g. bridge pier or overhead sign support) be 1.78m (5 ft 10 in), 1.37m (4 ft 6 in), and 1.19m (3 ft 11 in) for 12’6” (2x), standard 6’3” (1x), 3’ 1 ½” (1/2 x) post spacing, respectively.

These offsets are based on the “working width” deflections seen in the crash tests/analysis and include some degree of pickup truck penetration beyond the vertical plane of the barrier’s dynamic deflection. As with all traffic barriers, larger offset distances would be required to shield similar features from vehicles with higher centers of gravity, such as single-unit trucks or busses, because of the relatively high roll angles seen with these vehicles in rigid and semi-rigid barrier tests of similar height.

- 9) GMS-WB may be used with W-beam barrier terminals having equal rail heights.

- a) Test experience has shown that interchangeability is acceptable between other systems and terminals.

Because the crash testing met the requirements of the proposed MASH-08 criteria, the system described above, as well as the variations 1 through 9, are acceptable for use on the NHS under the range of conditions tested, when such use is acceptable to a transportation agency.

Please note the following standard provisions that apply to the FHWA letters of acceptance:

- This acceptance is limited to the crashworthiness characteristics of the systems and does not cover their structural features, nor conformity with the Manual on Uniform Traffic Control Devices.

- Any changes that may adversely influence the crashworthiness of the system will require a new acceptance letter.

- Should the FHWA discover that the qualification testing was flawed, that in-service performance reveals unacceptable safety problems, or that the system being marketed is significantly different from the version that was crash tested, we reserve the right to modify or revoke our acceptance.

- You will be expected to supply potential users with sufficient information on design and installation requirements to ensure proper performance.

- You will be expected to certify to potential users that the hardware furnished has essentially the same chemistry, mechanical properties, and geometry as that submitted for acceptance, and that it will meet the crashworthiness requirements of the FHWA and the NCHRP Report 350.

- To prevent misunderstanding by others, this letter of acceptance is designated as number B-150B and shall not be reproduced except in full. This letter and the test documentation upon which it is based are public information. All such letters and documentation may be reviewed at our office upon request.

- The GMS-WB guardrails and median barriers are patented products and considered proprietary. If proprietary systems are specified by a highway agency for use on

- Federal-aid projects, except exempt, non-NHS projects: (a) they must be supplied through competitive bidding with equally suitable unpatented items; (b) the highway agency must certify that they are essential for synchronization with the existing highway facilities or that no equally suitable alternative exists; or (c) they must be used for research or for a distinctive type of construction on relatively short sections of road for experimental purposes. Our regulations concerning proprietary products are contained in Title 23, Code of Federal Regulations, Section 635.411.

- This acceptance letter shall not be construed as authorization or consent by the FHWA to use, manufacture, or sell any patented system for which the applicant is not the patent holder. The acceptance letter is limited to the crashworthiness characteristics of the candidate system, and the FHWA is neither prepared nor required to become involved in issues concerning patent law. Patent issues, if any, are to be resolved by the applicant.

Sincerely yours,

David A. Nicol, P.E. |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||